The Versatility and Importance of Automatic Crimping Machines in Modern Industries

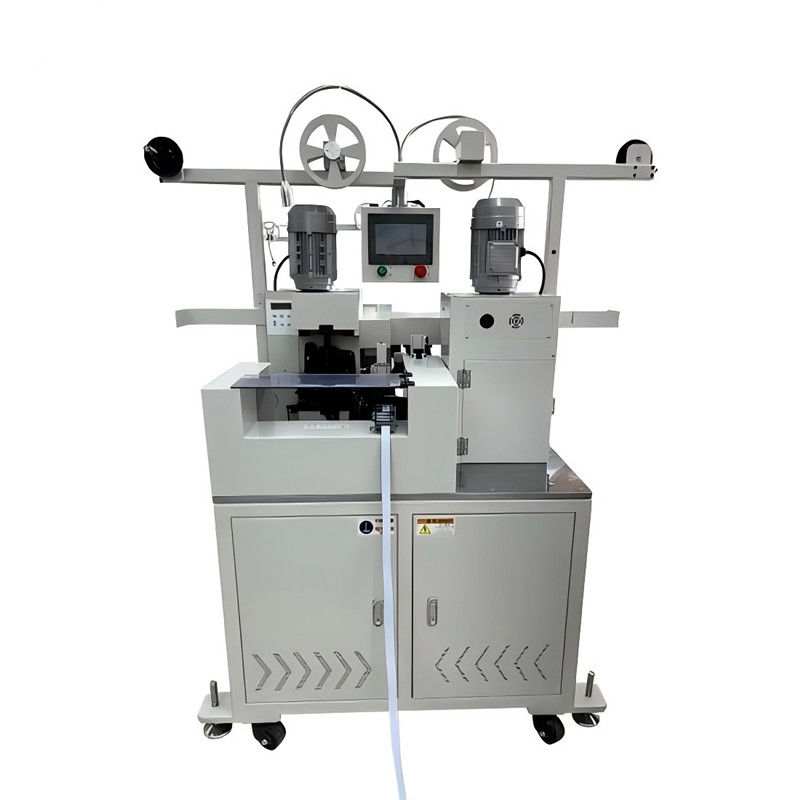

China Automatic Electric Wire Crimping Machine Maker

The automatic crimping machine plays a vital role in a variety of industries, providing efficient, reliable, and high-quality crimping solutions for numerous applications. From the automotive sector to electronics, and even in the manufacturing of electrical wires and cables, the automatic crimping machine is a key piece of equipment that ensures consistency and precision in the crimping process. The automatic crimping machine is designed to automate the crimping of terminals onto wires, providing a fast and effective solution that can increase productivity while reducing human error.

In the automotive industry, where wiring systems are complex and varied, the automatic crimping machine is essential for ensuring the integrity and reliability of electrical connections. With thousands of electrical components in modern vehicles, proper crimping is critical to ensure strong and secure connections. An automatic crimping machine provides a quick and efficient way to crimp connectors onto wires, offering consistent results that meet the rigorous quality standards of the automotive industry. These machines are capable of handling a wide range of wire sizes and connector types, allowing for flexibility in production lines. Their speed and accuracy help reduce labor costs and improve the overall efficiency of automotive manufacturing processes.

Similarly, in the electrical cable and wire manufacturing industry, automatic crimping machines are indispensable for mass production. These machines are used to attach terminals to the ends of wires and cables, creating a secure and electrically conductive connection. The automatic crimping machine ensures that every crimp is uniform and performs according to the set standards, which is critical in maintaining the safety and reliability of electrical systems. For industries where wire and cable assemblies are produced in large quantities, automatic crimping machines help meet the demand for high-volume production while ensuring the quality of each connection.

In the electronics sector, automatic crimping machines are often used to attach connectors to cables that are later used in complex electronic devices. The demand for precision and accuracy in the crimping process is high, as even small defects in the crimp can affect the functionality of sensitive electronic devices. The automatic crimping machine meets these stringent requirements by delivering a consistent crimp every time, ensuring that electronic components work as intended. These machines can handle delicate wires and tiny connectors, making them suitable for applications in everything from consumer electronics to advanced telecommunications equipment.

The benefits of using an automatic crimping machine extend beyond just efficiency and accuracy. By automating the crimping process, manufacturers can improve their overall production rates while reducing the risk of injury to workers who would otherwise perform manual crimping tasks. These machines reduce operator fatigue and ensure that crimping is performed with a high level of consistency, which can be difficult to achieve with manual processes. Furthermore, automatic crimping machines often come with built-in quality control systems that monitor every crimp to ensure it meets specific parameters, further enhancing the overall quality of the final product.

Automatic crimping machines are also highly customizable, making them suitable for a variety of industries with unique crimping needs. In addition to standard crimping applications, these machines can be equipped with specialized tooling to crimp a wide range of connectors, including ring terminals, spade terminals, and more. Many modern automatic crimping machines are also equipped with advanced features such as programmable settings, allowing users to adjust the machine’s parameters to suit different wire gauges or terminal types. This versatility makes the automatic crimping machine a valuable tool for industries with diverse crimping requirements.

As the demand for automation in manufacturing continues to rise, the role of the automatic crimping machine will only become more important. The ability to quickly adapt to new products and production requirements is a significant advantage for industries that must remain competitive in a fast-paced global market. With the growing importance of quality and efficiency, the automatic crimping machine has become an essential tool for manufacturers across a wide range of sectors.

In conclusion, the automatic crimping machine has revolutionized the way industries approach the crimping process. From automotive manufacturing to electronics and wire production, these machines provide a fast, reliable, and cost-effective solution for securing electrical connections. By automating the crimping process, businesses can achieve higher productivity, improved quality, and greater flexibility in their operations. As technology advances, the automatic crimping machine will continue to evolve, meeting the needs of industries around the world and helping companies stay ahead in an increasingly competitive marketplace.

EN

EN  English

English русский

русский Español

Español عربى

عربى